The Challenge:

designing a software from scratch capable of communicating with various hardware

The Result:

a robust system thanks to exception handling

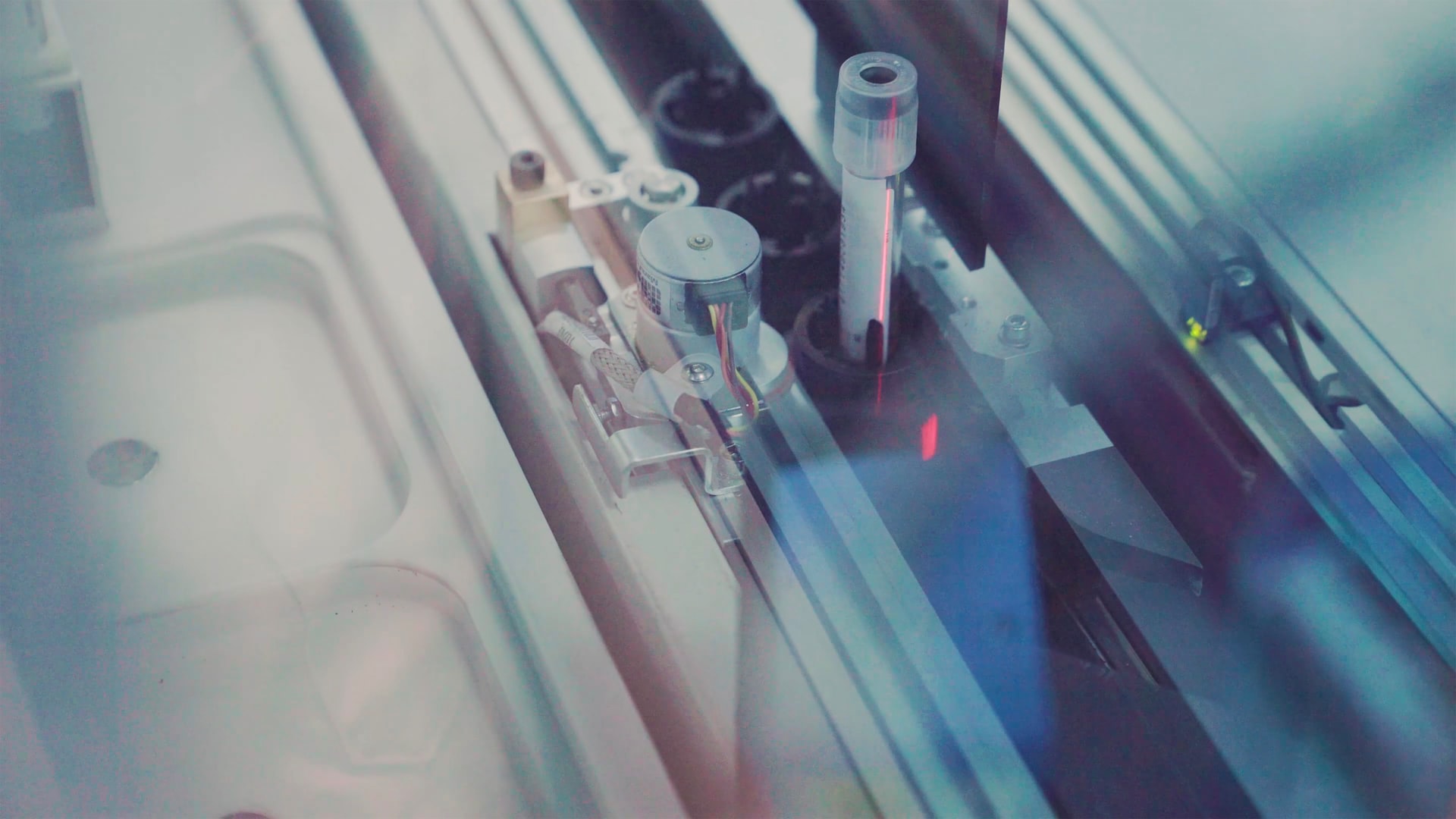

The customer’s project consisted of the construction of a high-precision automatic measuring machine to characterize brass wedges (gibs), creating an .xls file with the values that the end user must use to recreate the geometries.

GaraGeeks has developed a software for the Windows environment, in C # language, which at low level drives the stepper motors (Schneider Electric), the various Keyence measurement lasers (accuracy of 0.002mm) and the limit switches.

The high-level features offer high machine automation, with exception management and a clear user interface for the operator.

The functions offered are:

- Homing when starting the machine

- Positioning of the wedge against the reference pins consent to the measurement

- Adjustment of the sensors on the fork (different heights on the z axis)

- Compilation of information in the user interface with the following data: wedge length, First Measurement offset and pitch

- Once the automatic measurement has started, the scan starts from SENSOR RESETTING and SENSOR OFFSET COMPENSATION

- Scan according to the set positions;

- Export of readings table in Excel format

- End of measure communication.